Infrared Water Cut Meter for Cost-Effective Individual Monitoring of Complex Wells

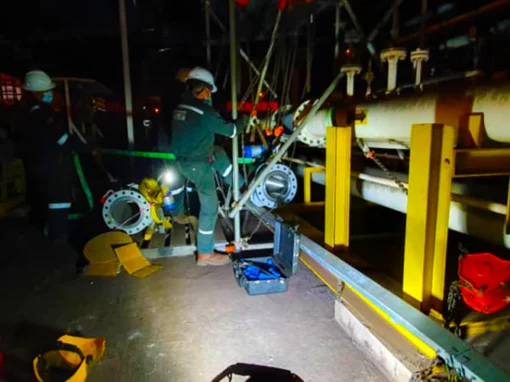

The infrared water-cut meter was used for the first time by Saudi Aramco for this specific application. The trial test was intended to verify the reliability of using infrared water-cut meters to provide cost-effective means of monitoring expensive horizontal wells. This real-time water-cut monitoring should enable remedial actions to take in a timely manner and, therefore, prevent potential loss on horizontal wells that is attributed to the uncontrolled water-cut increase.

The trial test is also intended to verify the practicality of using the infrared water-cut meter in areas that lack communication infrastructure. On the two wells tested, GSM technology was used to transmit well data to engineers’ office computers.

Drilling wells with long horizontal sections in many fields is standard practice. Drilling complex wells with multi-laterals is at an increasing trend. The cost of these wells is very high as opposed to conventional wells. The expenditure of such wells cannot be recovered if changes in water-cut go unnoticed, due to shortage of data, and eventually cause these wells to load up and die.

The only method that Saudi Aramco uses currently to acquire such data is through periodic well testing. This is a traditional well-testing technique that utilizes a test trap at the Gas Oil Separation Plant (GOSP). This technique limits the information available as such tests are periodic on a per well basis. The interval between good tests normally exceeds one month. This has increased the feasibility of real-time water-cut monitoring systems should they provide data with the required frequency and precision. Choosing the right application for real-time water-cut monitoring depends on how much data is required and how accurate it

needs to be. For evaluation purposes, measurement accuracy, data transfer capabilities, and cost-effectiveness played a major role.

There are various methods to measure the water-cut in a producing well. Methods for measuring water-cut values range from conventional hand sampling to real-time high-end technology measurement. By facilitating means for continuous water-cut monitoring, we ensure that the required information is available to take corrective action in a timely manner to better manage expensive good assets by maintaining well potential, managing water-cut conformance, and increasing the well life.

A real-time water-cut monitoring trial test was initiated in the Saudi Aramco Idea Management System. A multi-disciplined team was formed to evaluate and test the idea where applicable.

During the test, no major problems were encountered. The minimum water-cut measurement during the test was 5% and the maximum reached 42%. The meter was tested on oil wells with a GOR of ±550 Scf/STB. The post-test inspection of water-cut meters components indicated no corrosion at any of the water-cut meter components

0 Comments