Project Spotlight: Precision Under Pressure on a PETRONAS Offshore Metering System

In the vast expanse of the South China Sea, where Malaysia’s vital oil and gas operations take place, there are no small jobs. Every component, every action, and every decision carries immense weight. It is in this high-stakes environment that our team recently had the privilege of executing a critical upgrade for our esteemed partner, PETRONAS: the replacement of a Motorized Operated Valve (MOV) on a key fiscal metering system.

This wasn’t just a simple valve swap; it was a mission-critical project to safeguard the integrity, accuracy, and reliability of an asset that directly impacts the nation’s revenue.

The Challenge: The Unseen Importance of a Single Valve

Fiscal metering systems are the cash registers of the oil and gas industry. They measure the exact quantity of hydrocarbons being transferred from a platform to a pipeline or tanker. Their accuracy is non-negotiable and subject to stringent regulatory standards.

The MOV in question serves a vital function: positive isolation. During the critical process of meter proving (calibration), this valve must provide a perfect, leak-free seal to ensure a true zero-flow condition. Any leak, no matter how small, would render the calibration invalid and cast doubt on the accuracy of every measurement that follows.

The challenges were threefold:

Criticality: The valve’s performance was directly linked to fiscal integrity.

Environment: The harsh offshore conditions—salt spray, humidity, and vibration—demand robust and reliable equipment.

Lifecycle: The existing MOV was approaching its end-of-life, and a proactive replacement was essential to prevent a potential failure that could lead to measurement disputes or an emergency shutdown.

Our Solution: A Symphony of Onshore Planning and Offshore Execution

From our headquarters in Kuala Lumpur, our project team orchestrated a multi-phased approach grounded in precision and safety.

Phase 1: Meticulous Onshore Preparation

Before any technician set foot on the platform, the groundwork was laid. This involved detailed engineering to select a state-of-the-art MOV and actuator assembly specifically rated for the demanding service. The new unit then underwent a rigorous Factory Acceptance Test (FAT) at our facility, where we simulated its operational sequences, tested its integration with control signals, and verified its shut-off performance to ensure it was flawless before mobilization.

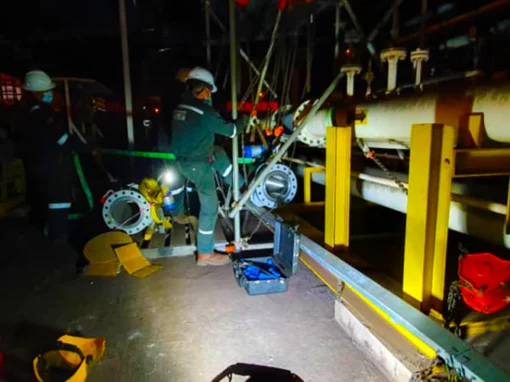

Phase 2: Seamless Offshore Execution

With a narrow operational window to minimize production impact, our offshore team executed the plan with surgical precision. Adhering to the highest safety standards—resulting in Zero Lost Time Injuries (LTI)—the team safely isolated the system, decommissioned and removed the legacy valve, and installed the new MOV. The mechanical, electrical, and instrumentation tie-ins were completed seamlessly, integrating the new hardware into the platform’s existing Distributed Control System (DCS).

Phase 3: Commissioning and Collaborative Handover

The final proof of success was the Site Acceptance Test (SAT). Conducted in close collaboration with the PETRONAS operations team, we performed a full suite of functional tests. We verified remote and local controls, confirmed stroke times, and most importantly, proved the valve’s tight shut-off capability under operational pressure. The successful SAT was the final handshake, confirming the new asset was fully operational and performing beyond expectations.

The Result: Reinforced Integrity and Future Peace of Mind

The successful completion of this project delivered tangible benefits for our partner, PETRONAS:

Enhanced Measurement Assurance: The new MOV guarantees reliable isolation, underpinning the accuracy and validity of all future meter proving activities.

Increased Operational Reliability: Proactively replacing an aging asset has eliminated a potential point of failure, contributing to the overall uptime of the platform.

Extended Asset Lifespan: The upgrade ensures the metering system will continue to operate at peak performance for years to come.

This project is a testament to the powerful synergy between meticulous engineering and collaborative partnership. We extend our sincere gratitude to the PETRONAS team for their trust and excellent cooperation throughout this venture. It is an honour to contribute to the operational excellence that defines Malaysia’s energy sector.

Is your facility facing challenges with aging critical assets? Contact us to discuss how our engineered solutions can enhance your operational integrity.

0 Comments