Enhancing Offshore Metering: A Deep Dive into an Electrical & Instrumentation Upgrade in Sabah

In the demanding environment of Sabah’s offshore oil and gas sector, ensuring the accuracy and reliability of fiscal metering systems is paramount. A recent site survey report for the Cili Padi platform provides a fascinating glimpse into the meticulous planning required for a critical electrical and instrumentation upgrade, showcasing the challenges and sophisticated solutions involved in modernizing offshore assets.

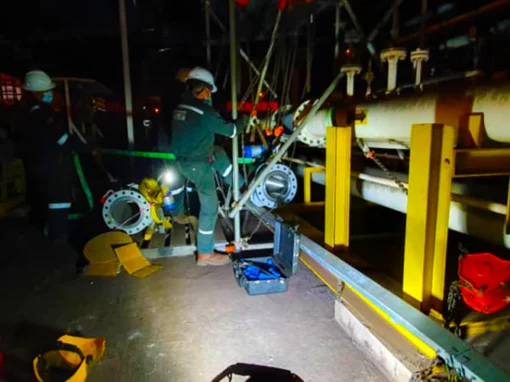

The project, undertaken by Ensetcorp for their client KROHNE / Shell, focused on the TEPU Condensate Metering Skid

On-Site Findings: The Real-World Challenges

The detailed site survey, conducted from June 16th to June 23rd, 2025, unearthed several crucial findings typical of aging offshore facilities

Power Limitations: The existing turbine meter operated on a 2-wire power signal system. This configuration was insufficient to power the local display unit, rendering it non-functional, and indicated a power constraint on the instrument loop

. Environmental Ingress: Several metering junction boxes were found filled with water, posing a significant risk to electrical connections and instrument reliability

Corrosion: A large number of stud bolts on the condensate metering skid’s flanges were badly corroded, compromising mechanical integrity and safety

.

These findings highlight the harsh realities of offshore operations and underscore the importance of thorough, on-site electrical & instrumentations Sabah surveys to identify hidden risks.

The Solution: A Modernized E&I Approach

The proposed solution involves replacing the old turbine flowmeter with a KROHNE OPTIMASS 6400 C Coriolis meter, a significant technological step-up

A key part of the upgrade is addressing the existing electrical limitations. The plan necessitates laying two new 86-meter cables

- dedicated Power Supply Cable to provide robust power for the new Coriolis meter and its electronics, including the local display

. - Diagnostic Cable (RS-485) to establish a digital communication link for advanced diagnostics, configuration, and data exchange with the control system

This new cabling is essential for unlocking the full functionality of the modern meter and integrating it into a centralized monitoring system

Physically, the new 721 mm Coriolis meter will replace the existing 180 mm turbine meter and adjacent pipe sections, including a flow straightener. The survey confirmed this can be done without major structural changes, as a 721 mm section of the main pipeline will be modified to accommodate the new installation

Mitigating Risks and Moving Forward

The report concludes that the replacement is feasible, pending final verification that the system’s maximum operating pressure does not exceed the new meter’s rating of 149 bar

Key recommendations include the immediate replacement of all rusted stud bolts and nuts on instrument flanges and rectifying the sealing on all affected junction boxes to prevent future water ingress

This project serves as an excellent case study on the complexities of brownfield modifications in Sabah’s offshore industry. It demonstrates that a successful outcome hinges not just on new hardware, but on detailed site assessments, meticulous planning for electrical and instrumentation integration, and a proactive approach to mitigating risks. Local expertise from companies like Ensetcorp Sdn Bhd is crucial for navigating these challenges and ensuring the long-term integrity and performance of critical offshore assets

0 Comments