What Is Flange Integrity Management?

Flange Integrity Management (FIM) is a methodology to ensure the integrity of flanged connections, minimizing and usually eliminating, integrity-related issues (such as leaks) at start-up or re-start. Moreover, FIM is related to a database with a complete history of every flange on a process plant. Registers, work packs, test packs, certificates, and drawing mark-ups are all created and modified in one system, giving increased efficiency and accuracy. FIM is a system that assures HSE performance and helps manage risks

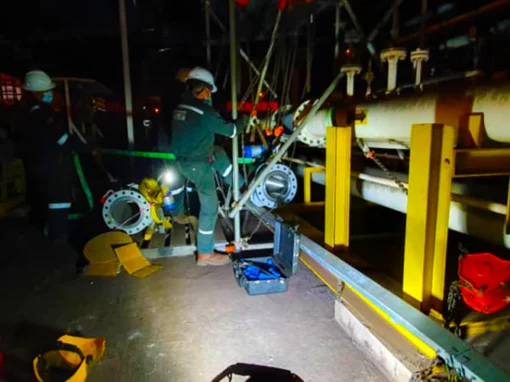

Flange Integrity Management Controlled Bolt Fastening Services

- The accurate application of torque or tension to flange stud bolts and nuts is critical

- Certified and calibrated equipment is a requirement

- All calibration must have tractability to national standards

- Trained and competent personnel are used to operate the equipment

Bolt Torquing

Precise control of applied torque and Compact equipment design

Bolt tensioning

Accurate application of tension State-of-the-art equipment.

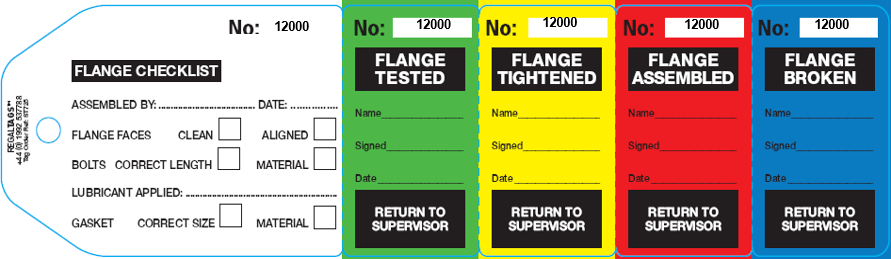

Four Part Flange Tag for Maintenance Projects

- Uniquely identify joints that are to be: Opened, Assembled, Tightened, Tested

- Each flange within the project work scope is ’tagged’

- The tags have multiple sections

- The colored sections are perforated to allow ‘tear off’

Flange Integrity Management Goal

- Leak-free bolted connections

- Trained competent personnel

- Calibrated and certified equipment

- Compliance with industry standards and best practice

Benefits

- Flawless start-up on time and within the budget of process facilities

- Minimized HSE and commercial risk associated with flanged connections

- World-class performance and efficiencies on both maintenance and construction projects

0 Comments