A water cut meter is a measuring device used to accurately monitor the amount of water present in crude oil streams. These meters are typically more sensitive than sensors used for production, with the capacity to detect concentrations ranging from 0 to 0.5%. It is important for accurate readings to be taken when exporting crude oil, as even small discrepancies in the readings can lead to considerable losses from having to pay more money for processed water and contamination costs.

The Importance of Measuring Water Cut in Oil and Gas

- Meeting quality specifications: Oil and gas have specific quality specifications that must be met for commercial use. The water content is an important factor in determining whether a sample meets these specifications.

- Efficient production: Water can interfere with the extraction and production of oil and gas, causing reduced production rates or damage to production equipment. By measuring the water cut, producers can take steps to optimize production and equipment operation

- Avoiding environmental contamination: Disposal of produced water can cause environmental contamination. Accurately measuring the water cut helps ensure that produced water is properly treated before being disposed of or reused.

- Accurate volume and revenue calculations: Oil and gas are sold by volume, so accurate measurement of the water cut is necessary to calculate the correct volumes produced. This is important for revenue calculations and tax assessments.

Variables Impacting Water Cut Sensors

- Calibration of Sensors is Required Due to Variations in Oil Composition. When Water Cut is Higher, Salinity Compensation is Needed and Conductivity Meters can Measure Water Salinity in Parts Per Million (ppm).

- Temperature Sensors are Necessary for Compensation in Water and Oil Emulsions, as Fluid Temperature Affects the Relationship between Dielectric Constant and Water Concentration. An Increase in Temperature Results in a Decrease in Dielectric Constant.

- Changes in Density Affect the Relationship Between Monitored Dielectric Constant and Water Concentration. Density Changes Due to Temperature Must be Compensated Using Temperature Sensors. For Systems with Multiple Liquids or Changing Liquid Mixtures that Cause Density Variations, Real-Time Density Compensation is Recommended by Connecting a Densitometer Input Directly.

Water Cut Measurement Technologies Currently Available in the Market

SeCap Technology

Similar to Other Water-in-Hydrocarbon Measuring Devices, SeCaP Sensor Exploits the Substantial Disparity in Electrical Properties (Permittivity) between Water and Hydrocarbons. Unlike Other Capacitance-based Water-in-Oil Monitors, SeCaP is a Single-Electrode Capacitance Probe. With SeCaP, the Secondary Electrode is Positioned Infinitely Away from the Primary Electrode. The Measured Fluid Absorbs the Alternating Charge Emitted by the Single Electrode, Similar to How Soil Absorbs Charge When Struck by Lightning. The SeCaP Sensor Offers Various Benefits Such As:

Exceptional Durability (Suitable for Temperatures Up to 225C and Pressures Up to 450 Bar) Compact Design (Measures Less Than 1″ in All Dimensions) Can Be Utilized as a Stand-Alone Sensor or Integrated into a Water Cut Meter.

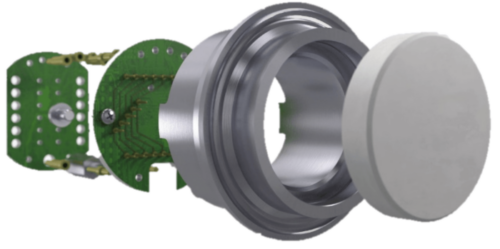

Capacitance Sensors

Water cut monitors use the principle of capacitance to measure the water content in oil. The cylindrical sensor and outer barrel form the electrodes of a coaxial capacitor, fixed in size and distance. The liquid sample flows between these plates, acting as a dielectric fluid, changing the capacitance of the assembly proportionally with the change in the fluid’s dielectric constant. The capacitance changes are then converted to a water content output signal by a microprocessor and associated components. Manufacturers like Delta-C claim their water cut meter can measure water content up to 0.5 vol% and as little as 100 ppm in oil streams

Microwave resonance Sensors

The Microwave Water Cut Meter employs microwave resonance technology to measure the permittivity of oil/water mixtures, exploiting the differences in dielectric properties of the two substances. Water measurement is achieved by transmitting microwave signals through the flow stream, and the signal changes with the water content

IR -Infra-Red Technology

An Infra-Red (IR) type water cut meter is a device used to measure the amount of water present in a hydrocarbon stream by using IR radiation. This type of water cut meter works by shining an IR beam through the hydrocarbon stream and measuring the amount of radiation absorbed by the water present in the stream. The amount of absorbed radiation is then used to calculate the water content of the hydrocarbon stream. IR-type water cut meters are commonly used in the oil and gas industry

Conclusion

Water Cut monitors are essential for maximizing the performance and value of a cut monitor. Factors such as accuracy, sensing range, process characteristics, mechanical configuration, maintenance requirements, and price should be taken into account when evaluating the various systems available. It is important to research and compare the various technologies in order to identify the features that best meet one’s individual needs. With the right information at hand, users can then make an informed decision on which technology best suits their requirements.

0 Comments

Trackbacks/Pingbacks