As an engineer, it’s important that you have a thorough understanding of the key aspects of hydrocarbon process measurement. This includes learning about the different types of data points associated with measuring gas, sand, and homogeneous flow so you can accurately analyze the hydrocarbon water cut. Here’s what you need to know.

Impact of Gas Presence in Hydrocarbon flow measurements on Microwave-Based Water Cut meter

Gas in the hydrocarbon pipeline can significantly affect microwave-type water cut measurements. Microwave signals are sensitive to changes in the dielectric properties of the fluid, and the presence of gas in the fluid can cause the signals to be scattered or absorbed, leading to inaccurate measurements of the water cut. The gas can also change the flow regime of the fluid, causing turbulence and affecting the distribution of the mixture, which further impacts the accuracy of water cut measurements. In order to mitigate the effects of gas on microwave-type water cut measurements, proper calibration and validation procedures must be implemented, and the sensor must be designed and installed in a way that minimizes the impact of gas on the fluid flow. Additionally, other technologies that are less sensitive to the presence of gas, such as SeCap Technology Sensors may be used in conjunction with microwave-type water cut meters to obtain more accurate measurements in the presence of gas.

Impact of Sand and Solids in Hydrocarbon Pipeline on Infra-Red Water Cut Measurement

Sand and solids in the hydrocarbon pipeline can adversely affect the accuracy of Infra-Red type water cut measurements. The presence of these particulates can cause signal attenuation and scattering, leading to measurement errors. Additionally, the accumulation of sand and solids on the optical window of the Red Eye sensor can reduce the clarity of the optical path, further affecting the accuracy of the measurement. To address this issue, regular cleaning of the optical window may be necessary, and proper filtering of the hydrocarbon stream may also be required

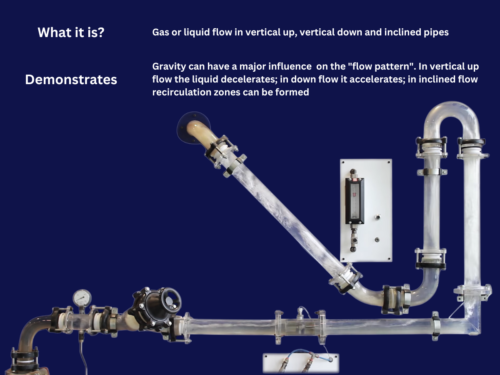

Importance of Homogeneous Hydrocarbon Flow and Minimum Flow Rate for Insertion Type Probe Water Cut Meters

The single probe or single sensor water cut measurements rely on homogeneous flow and minimum flow rate because the sensor is designed to measure the electrical capacitance of the fluid passing through it. If the flow is not homogeneous, meaning there are pockets of water or oil in the fluid, the capacitance measurement will be inaccurate. Similarly, if the flow rate is too low, the sensor may not be able to accurately measure the capacitance of the fluid passing through it. A minimum flow rate is necessary to ensure that the fluid is moving consistently across the sensor and that the sensor can take an accurate measurement.

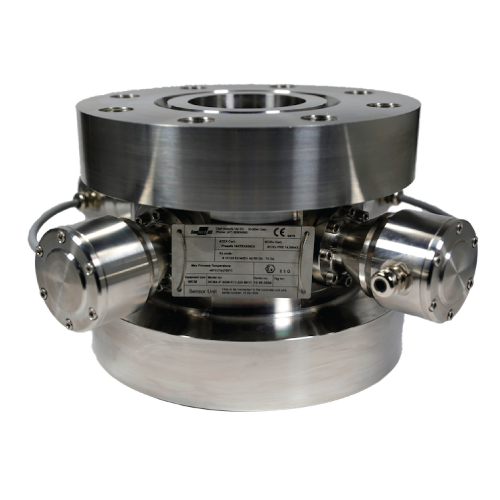

The Advantages of Sentech As Water Cut Meter in Challenging Hydrocarbon Flow Application

The Sentech As water cut meter is a technology that is effective in challenging applications such as the Oil Sand region of Canada, where there are high volumes of sand, calcium carbonate, and other solids. This water cut meter does not accumulate solids and can measure the water cut continuously as long as there is fluid flow. It is robust and capable of working in any type of operating condition, including unstable flow conditions. The meter utilizes multiple sensors to measure the water cut from different points in the pipe, which provides a much higher level of accuracy compared to other water-cut meter technologies that utilize a single sensor per meter. Additionally, the meter does not have any minimum flow rate or pipe straight length requirements and can detect the presence of gas pockets/gas slugs in the pipe without being damaged.

Sentech Water Cut

0 Comments